Gas chlorination systems are used to disinfect water and other purposes, such as in industrial and water treatment applications. Here are some details about gas chlorination systems:

Solubility of chlorine in water is very less, normally its below 0.5% of total volume of water, hence chlorination system is being used for disinfection of drinking water

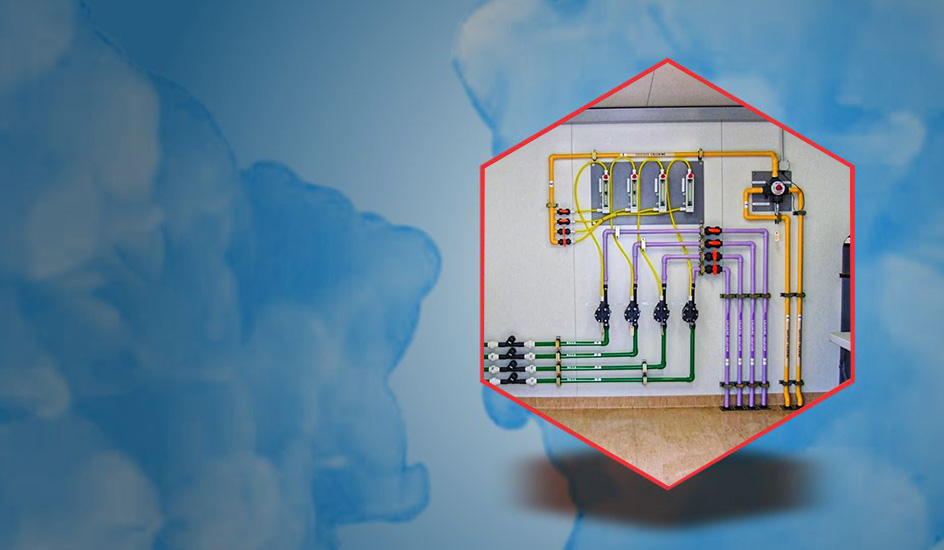

It includes rotameter, copper tubing attachment, centrifugal pump, ejector system. It can also be equipped with scrubber system and emergency kit, SCBA kit for more safe operation. Further it can be commissioned as per the requirement of site.

MOC: Nut and Collars are of extruded brass and pipe is of copper Used for connecting Hydrogen Cylinders with manifold. Can be supplied as per sample or drawing

Portable and wall mounting sensors for Chlorine,Hydrogen sulphide gas,Sulpher dioxide gas and carbon monoxide gases are available in different ranges with all certification. We also carry out AMC for these sensors.

MOC-Aluminium silicon bronze body with Monel Spindle, Brass washer and Teflon washer We can supply Chlorine container valves as per IS 3224 and as per Chlorine Institute of America

MOC:Naval Brass We can supply blind plugs as per IS-3224 and Fusible plugs as per Chlorine institute of America

These rollers are used for rolling container in case of any leakage. Leaky portion, valve of container must be taken in upper position to avoid leakage of liquid Chlorine from container as 1CC liquid Chlorine produces 460 CC of gaseous Chlorine hence leakage of liquid Chlorine must be avoided. For avoiding leakage of liquid Chlorine from container these roller stands are used.

MOC-Extruded brass fittings with Copper piping, Pressure gauge, PRV, Hydrogen Cylinder valve and Oxygen valve Used for connecting and mounting Hydrogen Cylinders of different water capacities in trucks. Can be supplied as per drawing or sample.

This kit is used for attending leakage in chlorine valves, container body or from plugs. With the help of this emergency kit chlorine leakage is contained but choline container has to be emptied out as fast as possible.

This kit mainly consists of tie rods, MS channel, EPDM packing, Hood for chlorine valve, copper tubing, clamps, gas masks, chemical splash-proof apron and many more.

SCBA is used for rescue operation in leakage of any toxic gas and also in case of fire.

SCBA cylinders are generally are of 2 types in regards of pressure

Generally bulk consumer of chlorine prefers chlorine evaporator system for smooth and continuous supply of chlorine. In chlorine Evaporation system liquid chlorine is vaporised in chlorine vaporiser. For vaporising chlorine either steam, water or electrically heated coil are used which are used as per the requirement of end user.

Chlorine evaporator system consists of evaporation unit, pressure gauges, NRVs, Gland valves and weighing scale. Also, it can also be equipped with scrubber system and emergency kit, SCBA kit for more safe operation

With TLV of 0.5 ppm chlorine is considered one of the most toxic elements on earth, but its widely used for disinfecting of drinking water, STP, in making bleaching powered, in sodium hypochlorite, in pesticides and many more.

Chlorine is generally stored in 900 kgs capacity chlorine container and or up to 100 kgs chlorine cylinder. From these storage containers chlorine is used by connecting with pipes. There are chances of leakage from the joints of pipe or from the system. This leakage of chlorine is controlled with help of chlorine scrubbing/neutralization system.

In chlorine Scrubbing system leakage of chlorine is absorbed in caustic solution with the help of chlorine blowers. Even large amount of leakage can also be controlled in same scrubbing system.

Chlorine Scrubber/neutralization system can be designed as per the plant requirement.